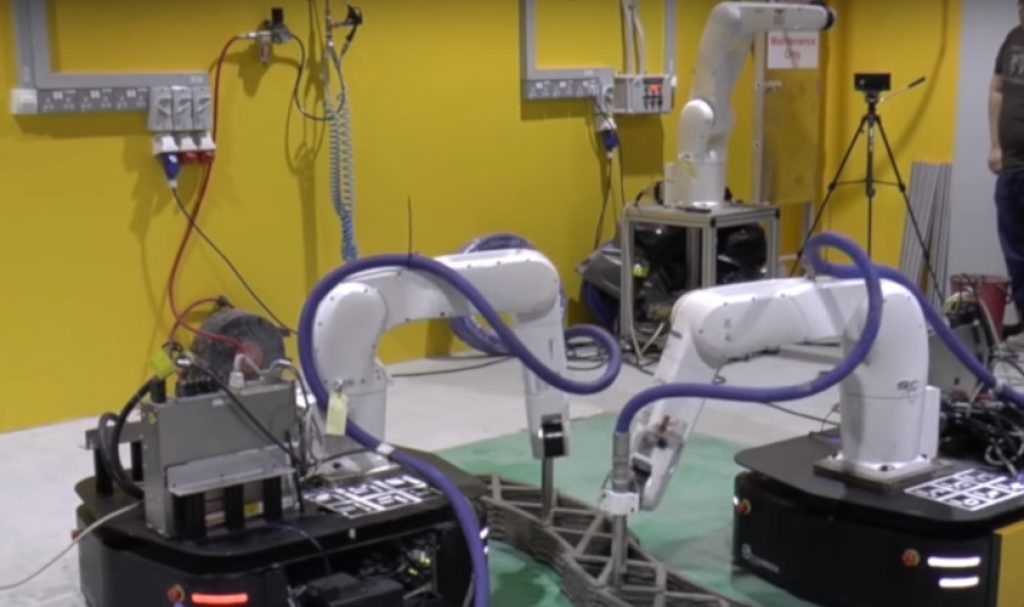

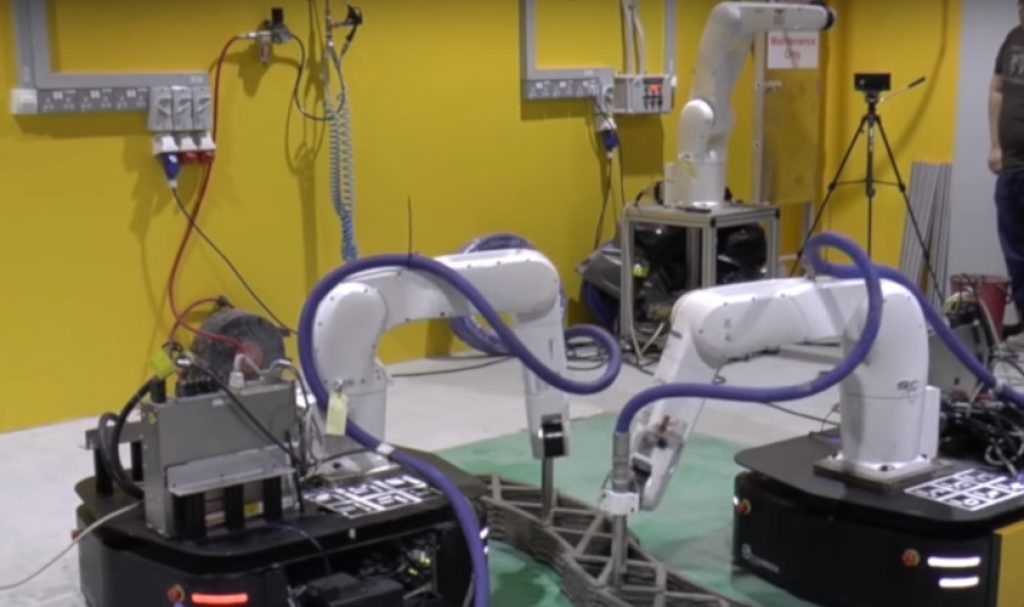

Scientists from Nanyang Technological University, Singapore (NTU) have developed a technology where two robots can work in unison to print a three-dimensional (3D) concrete structure. Their findings are published in Automation in Construction. The ability to 3D print large structures could be a boon for the construction industry, reducing material wastage and construction time. Currently, 3D printing of large concrete structures requires huge printers that are larger than the printed objects, which is unfeasible since most construction sites have space constraints. In this study, researchers led by Assistant Professor Pham Quang Cuong and his team at NTU’s Singapore Center for 3D Printing have tapped on swarm printing, whereby two robotic arms work in concert to create large 3D structures. Printing concrete structures concurrently with two mobile robots was a challenge as both robots had to move into place and start printing their parts without colliding into each other. Printing the concrete structure in segments is also not acceptable, as joints between the two parts will not bond properly if the concrete does not overlap during the printing process. The researchers solved these problems by first having a computer map out the design to be printed. They then assigned specific parts of the printing process to the two robotic arms, which relied on an algorithm to avoid collision during the concurrent printing. Using precise location positioning, the robots then moved into place and printed their assigned parts, ensuring that the joints between the separate parts are overlapped. Throughout the process, the specialized liquid concrete mix had to be blended evenly to ensure consistency. In eight minutes, the robots 3D printed a concrete structure measuring 1.86m x 0.46m x 0.13m, which took two days to harden and one week to achieve its full strength before it was ready for installation. Having multiple mobile robots that can 3D print in sync means that large structures like architectural features and specially-designed facades can be printed anywhere as long as there is enough space for the robots to move around the work site. “We envisioned a team of robots which can be transported to a work site, print large pieces of concrete structures and then move on to the next project once the parts have been printed,” said Pham. “This research builds on the knowledge we have acquired from developing a robot to autonomously assemble an Ikea chair. But this latest project is more complex in terms of planning and execution due to its much larger scale,” he added. Moving forward, the NTU research team will integrate more robots to print larger structures, optimize the printing algorithm for consistent performance and improve the concrete material for faster curing.

About the Author

This article is written by AsianScientist

Read the original post here.